Co-Founder – Angoera Sistemas Eletrônicos - angoera.com.br

I co-founded Angoera, a company focused on the custom development of electronic products — from concept to large-scale manufacturing. Angoera specialised in creating innovative solutions tailored to clients’ needs across a wide range of sectors, including agriculture, health, logistics, and consumer technology.

Our core offering combined a full-service approach with advanced technological expertise, guiding clients through every step of the product journey:

Ideation and concept validation,

Electronic and mechanical design,

Prototyping and industrialisation,

Field support and continuous improvement.

The company was also known for applying cutting-edge technologies such as wireless communication, IoT, low-power systems, artificial intelligence, and blockchain into embedded solutions.

As co-founder, I was responsible for leading the technical team, aligning project execution with engineering best practices and business goals. I often took an active role as an engineer in critical stages of development, while also acting as the main bridge between the technical team and the client — ensuring the delivery of robust, scalable products that met real-world requirements.

Our "Team as a Service" model enabled us to integrate seamlessly into client structures, accelerating time-to-market while maintaining flexibility, predictability, and high development standards.

In addition, Angoera fostered innovation through the creation of spin-offs, launching new companies around high-potential ideas developed in-house. This model allowed us to transform bold concepts into standalone businesses with focused market strategies.

Below are some of the key projects developed by Angoera, showcasing our approach to solving complex challenges through technology and design.

📌 Recognition: Angoera was ranked Top 10 in IoT in Brazil’s Top 100 Startups ranking for two consecutive years. This national recognition highlighted our consistent innovation and leadership in the Internet of Things ecosystem, affirming our position among the country’s most promising technology companies.

Dr. Freeze® – Nasopharyngeal Catheter for Therapeutic Temperature Control

Medical device for selective brain cooling, approved by ANVISA, designed to increase patient safety in cases of severe brain injury through Therapeutic Temperature Control (TTC).

🛠️ My Role:

Led the development of the electronic and thermal control system from concept to clinical validation.

Collaborated with medical and regulatory teams to ensure compliance with ANVISA standards for life-support equipment (RDC 185/2001, RDC 16/2013, and related regulations).

Designed the temperature control system with 0.01 °C precision, based on advanced PID algorithms.

Integrated power management for Peltier cells up to 1500 W each, ensuring rapid and reliable response.

Developed firmware using FreeRTOS, with multiple safety and control modules:

→ Thermal PID control | Fault detection and handling

→ Supervision of pumps, pressure, ventilation, and reservoir level.Coordinated laboratory and hospital trials to validate efficiency, safety, and reliability.

⚙️ Key Technologies:

High-precision PID temperature control (0.01 °C)

1500 W Peltier cells with dedicated power control

Cooling system with air tunnels and PWM-controlled fans

Human–machine interface: 7’’ display, alarms, fault management

Firmware on FreeRTOS with multiple safety layers

Advanced sensing: temperature, pressure, pumps, airflow, reservoir level

Battery management system for backup operation

Regulatory compliance with ANVISA: RDC 185/2001, RDC 16/2013, RDC 751/2022 (medical device registration)

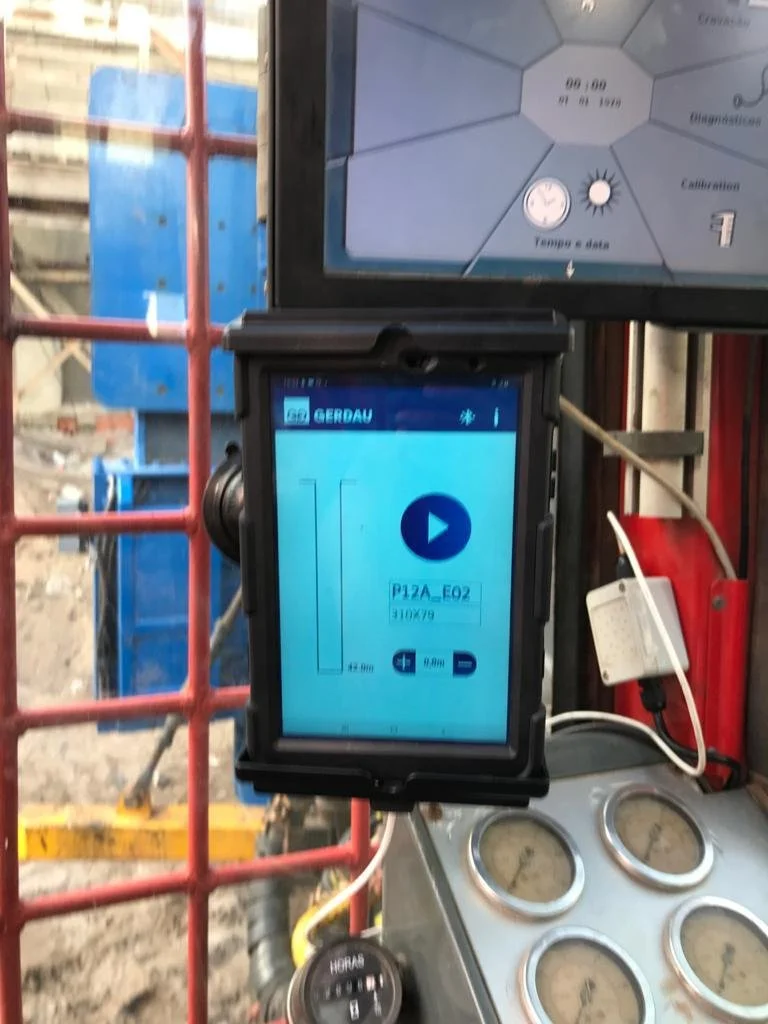

Pile Driving Management System for Civil Construction

Real-time monitoring and data collection to optimise pile installation on construction sites

🛠️ My Role:

Defined the complete product architecture and technical strategy

Worked closely with the client to understand operational needs and translate them into product requirements

Acted as Project PMO, overseeing the solution design and ensuring alignment with construction site constraints

Developed the hardware for the sensor system, including mechanical robustness and environmental resistance

Led the firmware development, ensuring accurate high-frequency data acquisition and reliable wireless communication

⚙️ Key Technologies:

BLE communication

High-impact accelerometers

30m-range LIDAR

NRF52840 microcontroller

Zephyr RTOS

Custom embedded peripherals

Smart Waste Bin Barcode Scanner

IoT device for automating household shopping lists based on waste bin data.

🛠️ My Role:

Led the development of the product from concept to deployment

Collaborated closely with the client to understand market needs and define key features

Designed low-power hardware tailored to usage patterns near household waste bins

Developed firmware using Espressif MCUs, enabling Wi-Fi communication and cloud integration

Translated consumer behaviour insights into a technically feasible and scalable solution

⚙️ **Key Technologies:**

- Low-power design

- Presence detection

- Barcode scanning

- **Wi-Fi (ESP32)**

- **Embedded firmware development**

Wireless Fire Alarm System

Complete wireless fire alarm solution designed for safety-critical environments using proprietary RF and Nordic technology

🛠️ My Role:

Designed the communication architecture using a proprietary RF protocol

Worked alongside the client to define functional and market requirements

Led the productisation process, managing the transition from prototype to production-ready hardware

Developed firmware for all devices in the system—from control units to battery-powered endpoints

Contributed to the definition of compliance and robustness criteria for the final product line

⚙️ Key Technologies:

Proprietary RF protocol

Microchip microcontrollers

Nordic wireless technology

Low-power embedded systems

Custom firmware development

🔗 The full product line can be viewed at: www.walmonof.com.br

IoT Tap System for Draft Beer Consumption

Smart beer tap solution enabling precise measurement and control of beer dispensing in hospitality environments.

🛠️ My Role:

Defined the complete product architecture, focusing on low-power wireless communication and precise volume tracking

Designed and implemented the firmware for the CC1310 microcontroller, optimised for reliable data transmission over the 915 MHz network

Integrated flow sensor data with embedded logic to calculate consumption in real-time

Developed the communication protocol between the tap devices and the central concentrator unit

Ensured end-to-end data flow from physical dispensing to cloud APIs, guaranteeing compatibility with the main application

Supported the mechanical design team to ensure the solution was robust and suitable for bar environments

⚙️ Key Technologies:

CC1310 ultra-low-power microcontroller

915 MHz sub-GHz RF mesh network

Flow sensor with pulse output for volume measurement

Raspberry Pi as central concentrator with Wi-Fi and API integration

Real-time data forwarding to cloud-based platforms

Custom protocol for tap identification and dispensing tracking

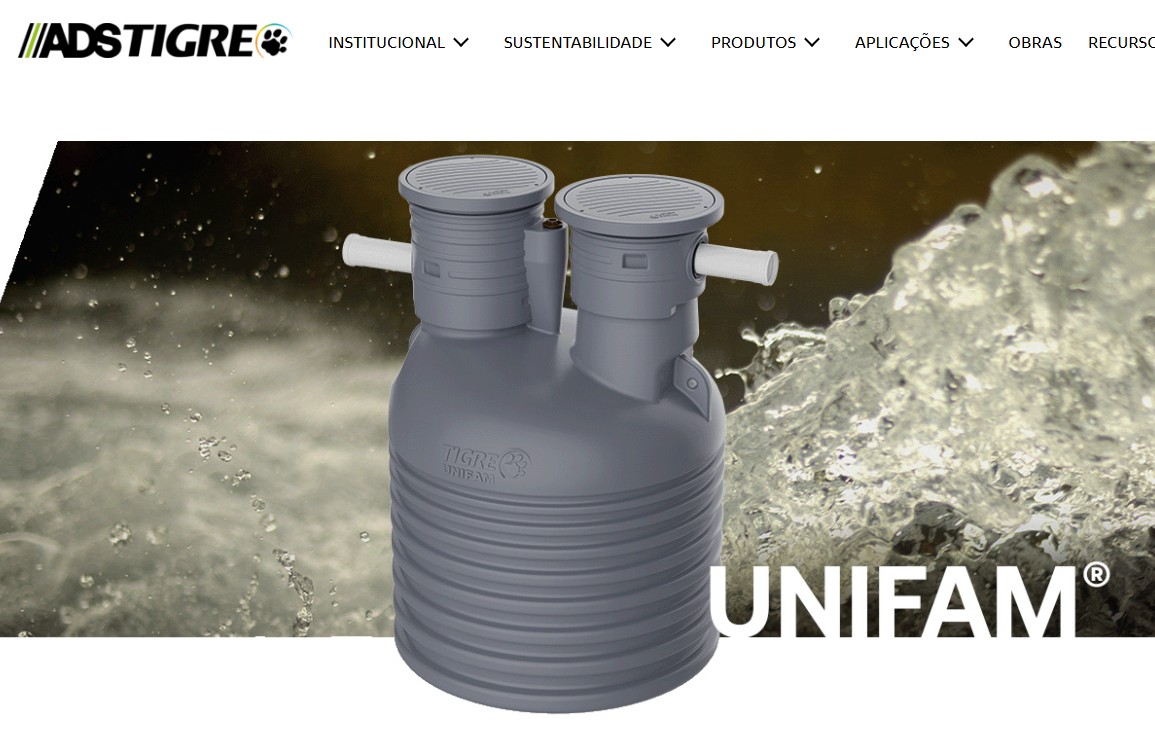

Tigre Unifam – Decentralized Wastewater Treatment System

Sustainable and efficient sanitation solution for areas without sewage collection networks

🛠️ My Role:

Designed the electrical and electronic systems architecture of the product

Developed the control panel hardware, including blower integration, alarms, and operation modes (normal, party, vacation)

Implemented the firmware development for reliable system monitoring, operation safety, and energy efficiency

Ensured electrical protection and safety compliance, integrating sensors, actuators, and control logic

Worked on power management optimisation, enabling low energy consumption and robust operation in rural and urban environments

⚙️ Key Technologies:

Aerobic biological treatment with immobilized biomass on porous biomedia

Electronic control panel with user-friendly modes and alarm functions

Air blower system with diaphragm technology and coarse bubble diffusers

Custom electrical components: sensors, actuators, and safety relays

Energy-efficient operation with continuous monitoring

High-resistance materials (recycled polyethylene, polypropylene, PVC, PU)

Scooter Tracking Solution

Development of a 4G and GNSS-based tracking solution for pre-mounted electric scooters. The project involved not only the hardware and firmware integration but also technical adaptations for physical protection and reliable installation of the devices in the scooter chassis.

This solution was successfully deployed in more than 10,000 scooters.

Key technologies: 4G cellular connectivity, GNSS positioning, ruggedised hardware integration, and embedded firmware development.

Equine Birth Prediction System

AI-driven sensor platform to accurately forecast foaling in mares using biometric and behavioural data

🛠️ My Role:

Conducted a scientific and technical investigation to correlate biometric and behavioural signals with the birth cycle

Designed and built a custom elasticity sensor with BLE communication for vulva dilation detection

Developed both hardware and firmware for the sensors and communication gateway

Collaborated with veterinarians and field teams to validate sensor effectiveness and define foaling prediction logic

Developed a backend-enabled AI algorithm to estimate the delivery window with high precision

⚙️ Key Technologies:

BLE communication

4G/Wi-Fi gateway

Custom elasticity sensors

Embedded AI-based detection

Low-power hardware design

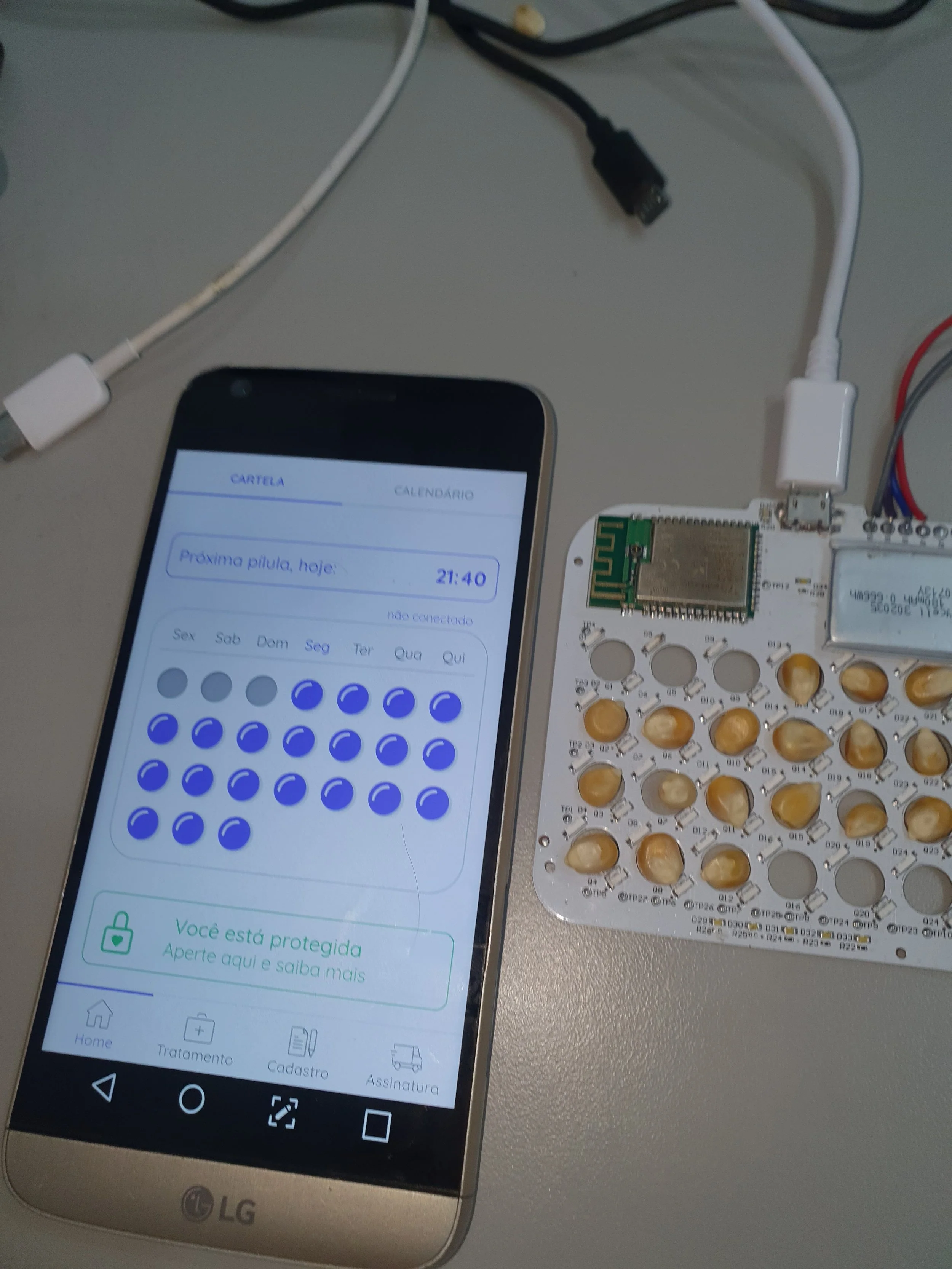

Smart Contraceptive Blister Pack

AI-enabled pill tracking device to ensure adherence to contraceptive protocols through embedded sensors and BLE communication

🛠️ My Role:

Led the mechanical design of a high-precision blister system with embedded presence sensors in each pill cavity

Developed the firmware and hardware architecture using the Nordic nRF52840, optimised for ultra-low-power operation

Integrated BLE communication for seamless synchronisation with a companion mobile app

Embedded the full contraceptive cycle logic within the device to guide daily usage and monitor user adherence

Designed and implemented the notification system to alert users via mobile app in case of missed or irregular usage

⚙️ Key Technologies:

BLE communication (Nordic nRF52840)

Precision presence detection sensors

Embedded cycle logic and adherence tracking

Ultra-low-power hardware architecture

App-based notifications and data synchronisation

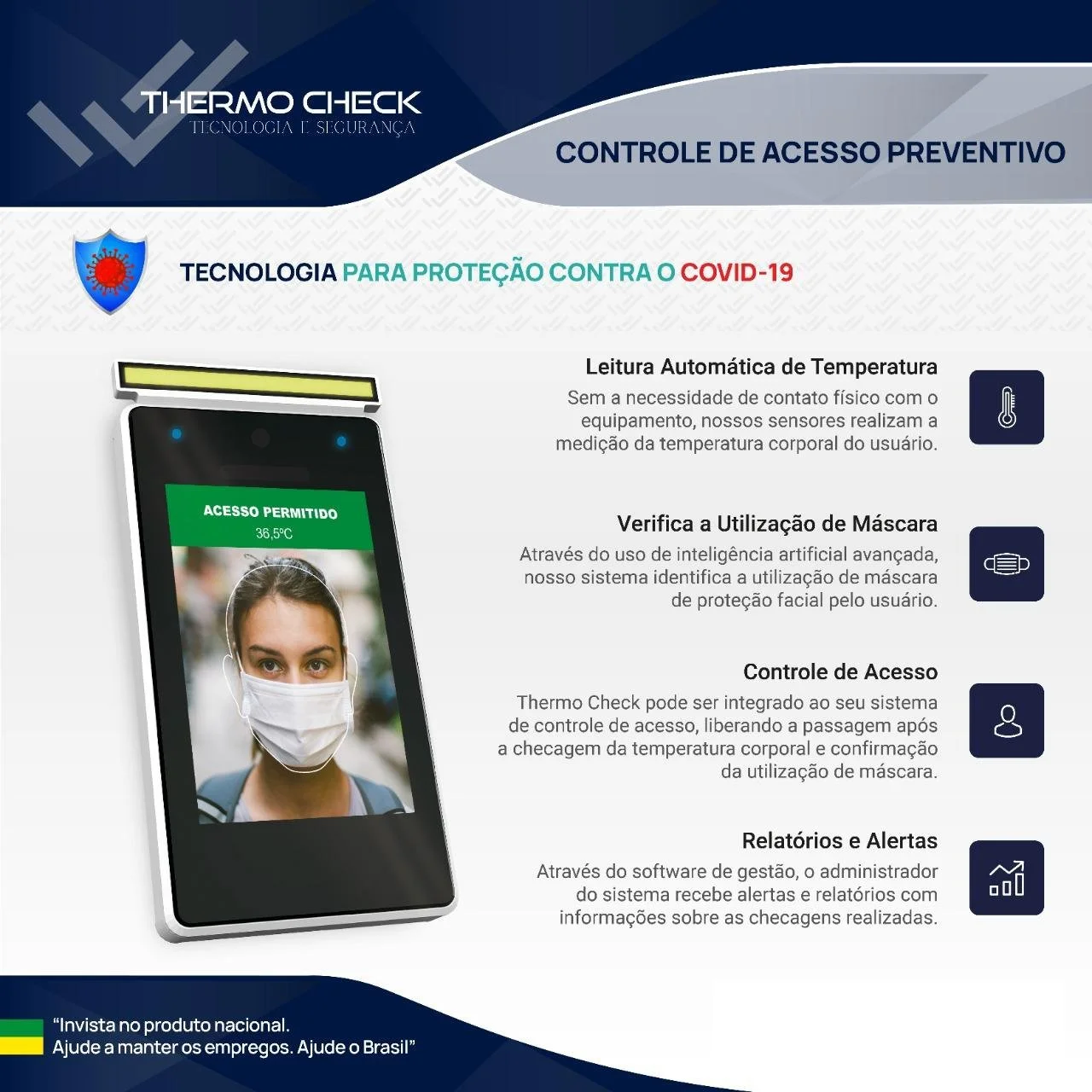

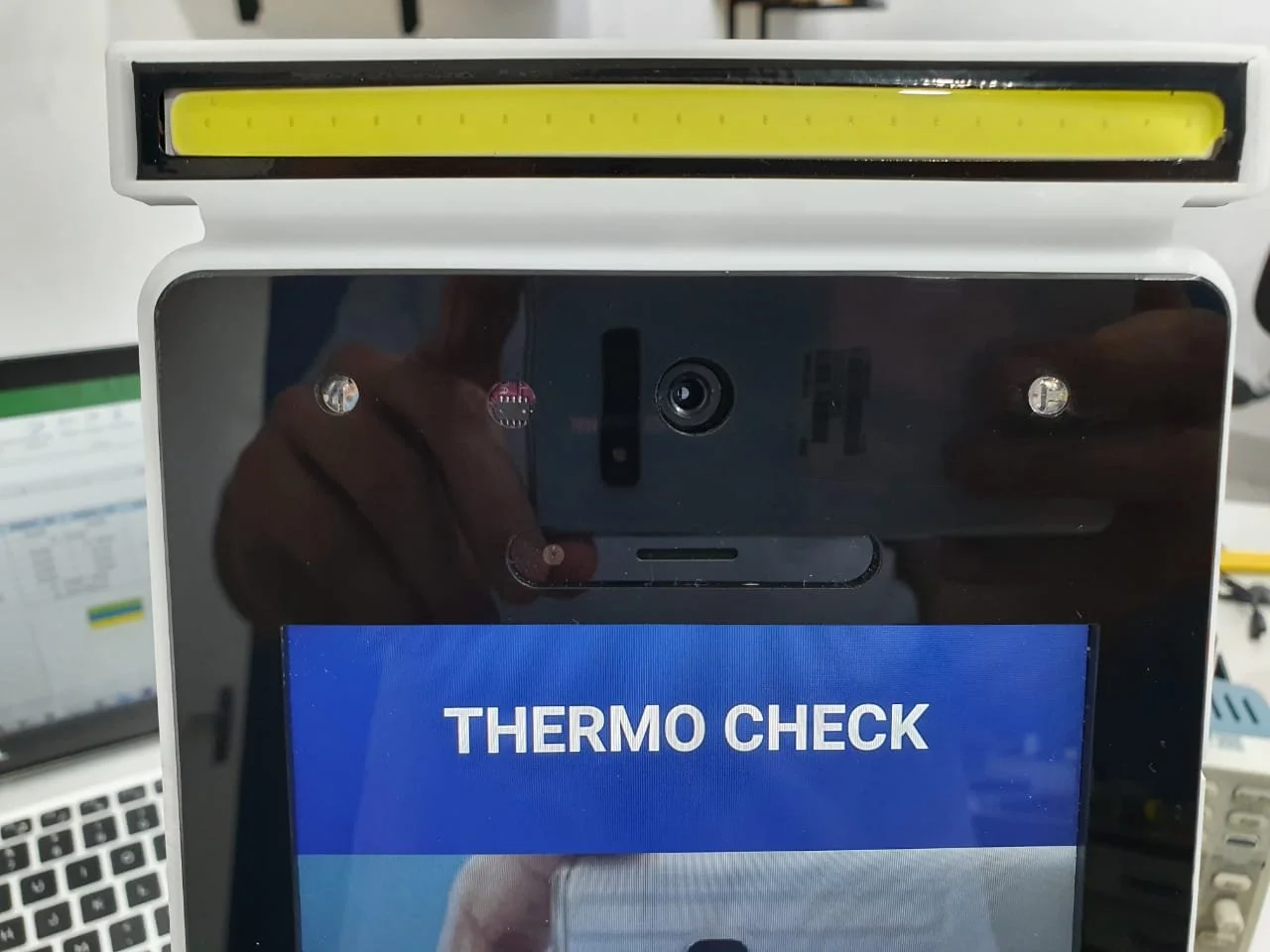

Contactless Temperature and Face Mask Detection System

Non-intrusive health screening using embedded AI and computer vision for COVID-19 safety monitoring

🛠️ My Role:

Led the end-to-end development of the product, including embedded hardware, firmware, and cloud integration

Created and trained a TensorFlow-based model for face mask detection via computer vision

Integrated long-range infrared temperature sensing and presence detection for safe, contactless screening

Structured the business model and go-to-market strategy, including distribution and sales channels

Drove the entire spin-off initiative within Angoera, from technical architecture to market deployment

⚙️ Key Technologies:

Custom embedded hardware

BLE communication

Long-range infrared sensing

TensorFlow (face mask detection)

Edge AI

Business development & sales structuring

Alcohol Dispenser with Integrated Marketing Totem

A simple yet effective alcohol dispenser developed during the COVID-19 pandemic, featuring an integrated screen for digital signage and media display. The system combined hygiene functionality with marketing, allowing content to be broadcast while providing hand sanitiser in public spaces.

I was responsible for the development of the hardware and firmware, which included controlling a dispensing pump and managing presence sensors for touchless operation.

Key technologies: Embedded hardware, presence detection, pump control, digital signage integration.

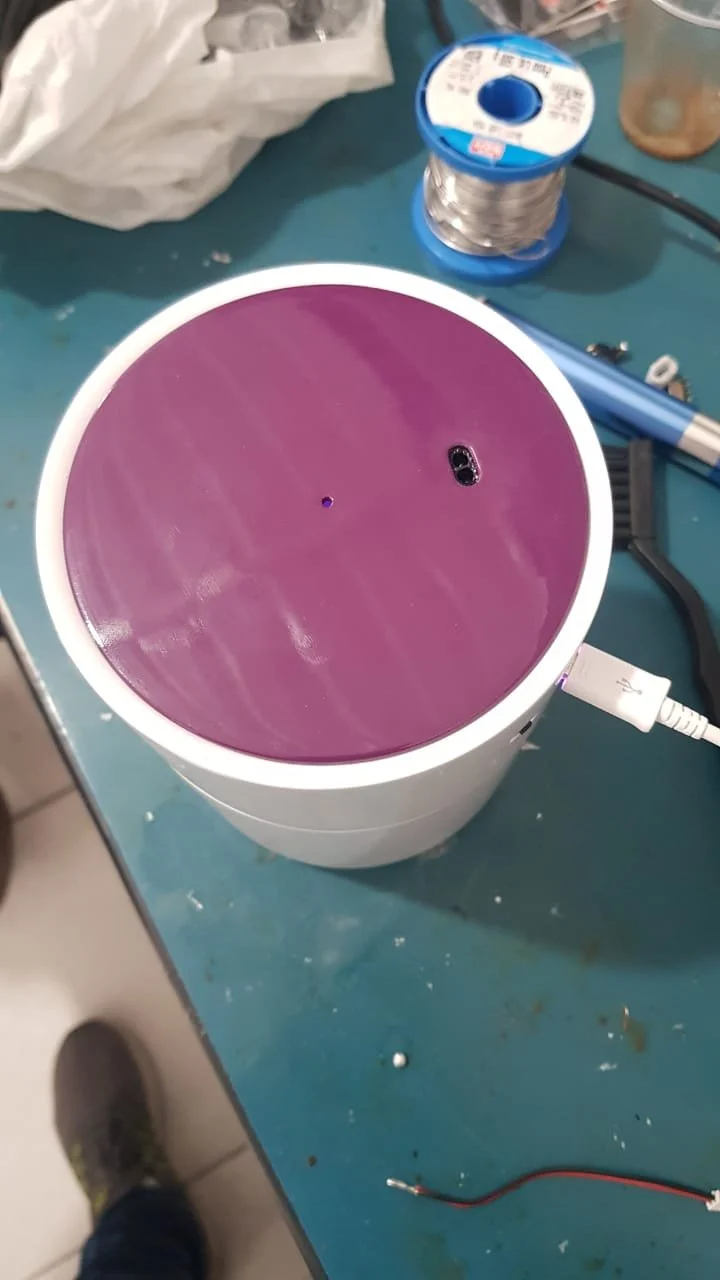

Battery-Powered Mobile Alcohol Dispenser with Proximity Sensing

🛠️ My Role:

Led the hardware design and system integration for the complete embedded solution

Implemented an infrared proximity sensor to ensure reliable hands-free activation

Integrated a servo motor for precise dosage control and fluid delivery

Developed firmware for real-time control, sensor responsiveness, and power efficiency

Designed the system to operate on a rechargeable battery, enabling portability and flexibility in deployment

⚙️ Key Technologies:

Infrared proximity sensing

Servo motor control

Rechargeable battery system

Low-power embedded firmware

Efficient power management design

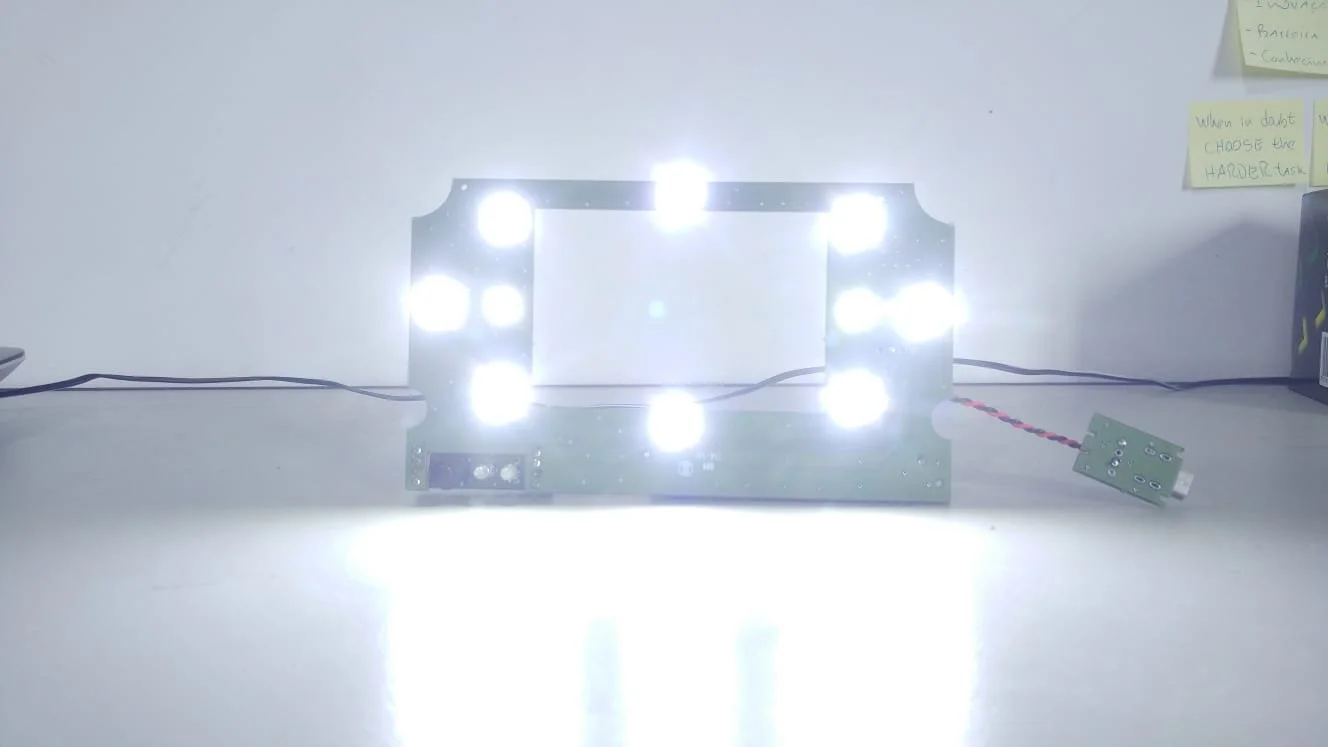

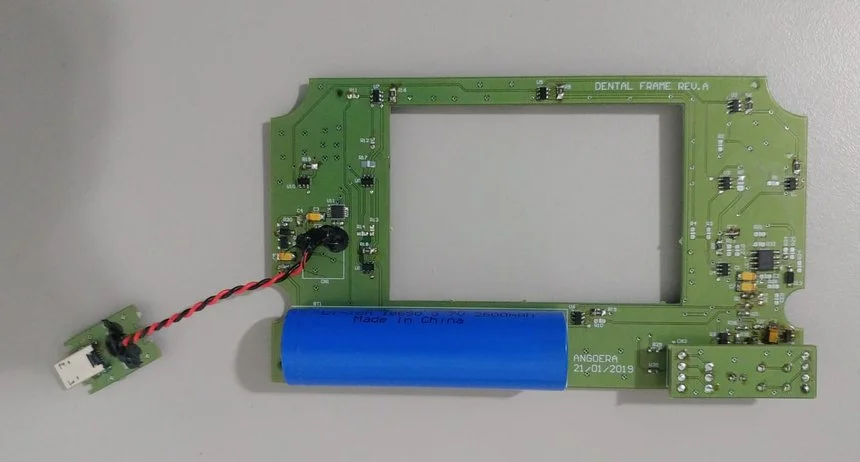

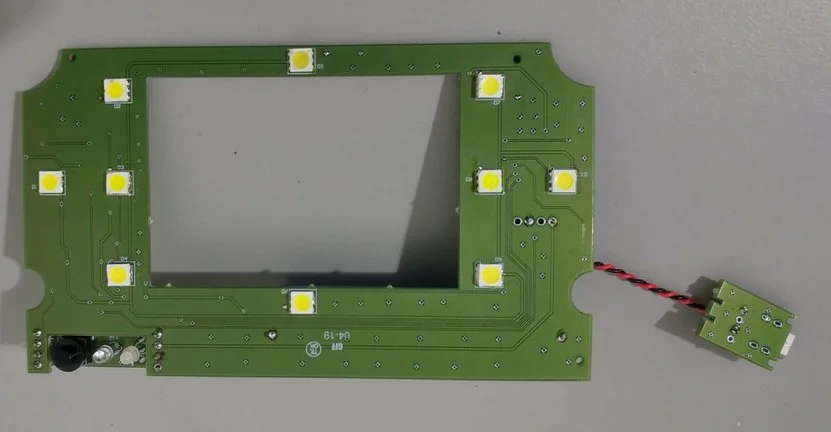

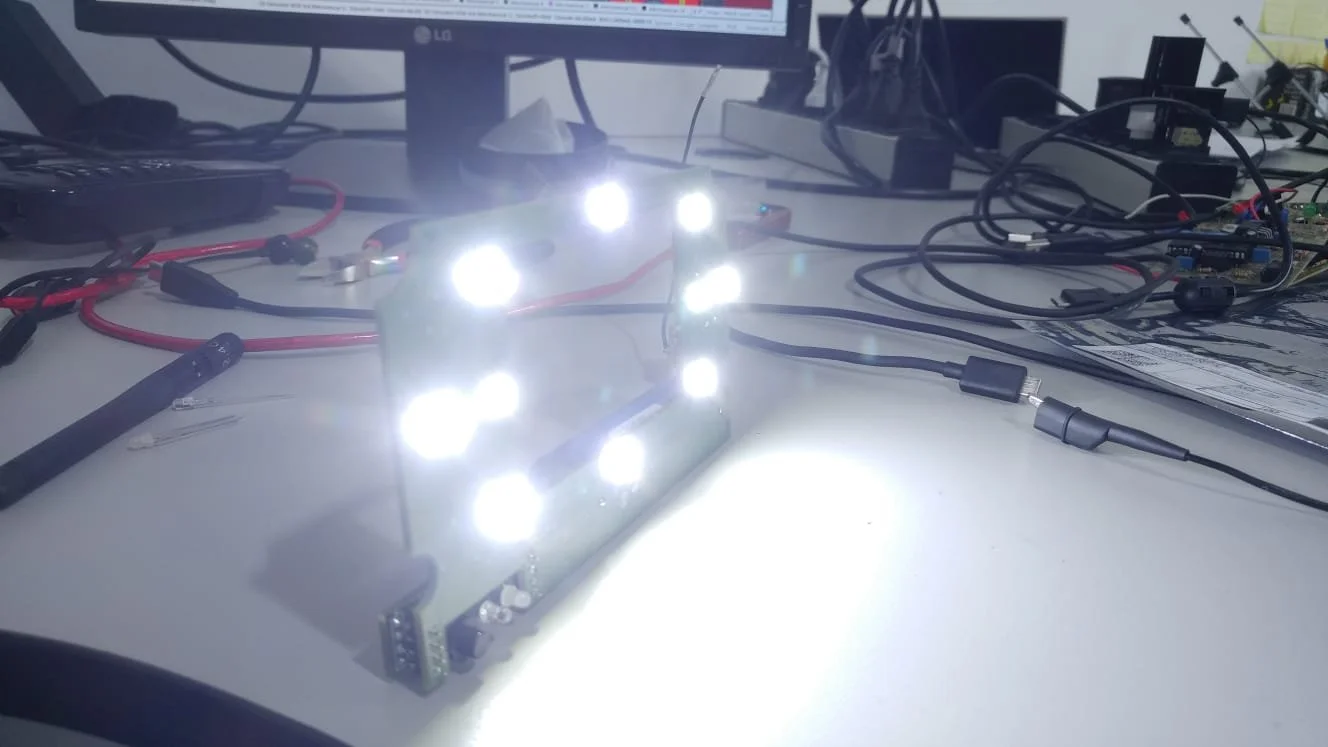

High-Power LED Illumination for Dental Image Capture

Precision lighting system designed for consistent and high-quality dental imaging

🛠️ My Role:

Designed the complete hardware architecture for the LED lighting system

Implemented a constant-current LED driver to ensure precise and stable light output

Developed digital control logic without a microcontroller, reducing system complexity and cost

Created a circuit to manage colour temperature and brightness via intensity and tone adjustments

Ensured stable and uniform illumination critical for high-resolution dental image capture

⚙️ Key Technologies:

Constant-current LED driver

Digital logic control (no MCU)

Colour temperature & brightness control

High-power LED circuitry

Precision analog electronics

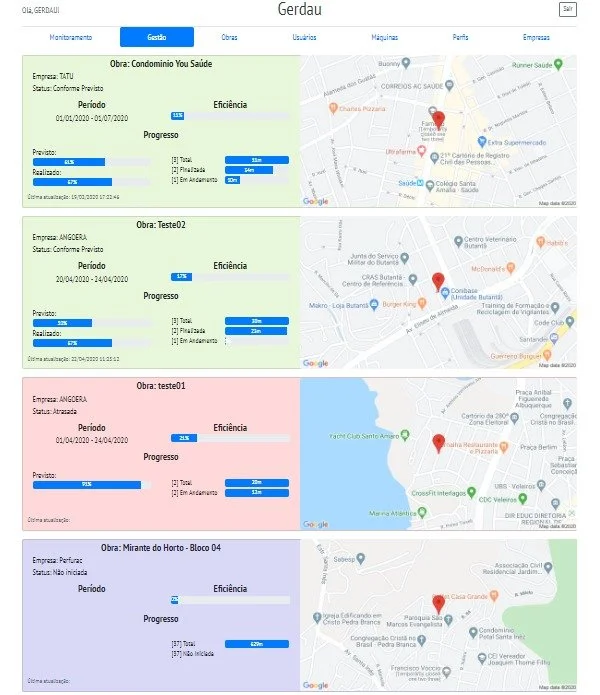

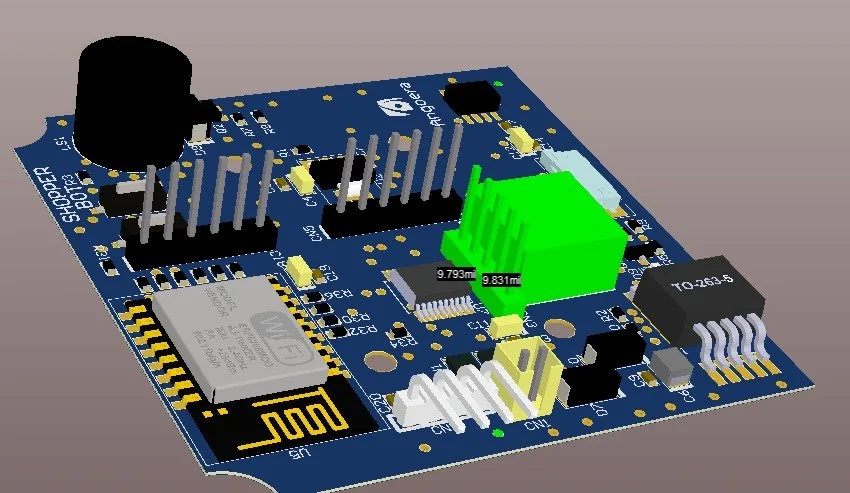

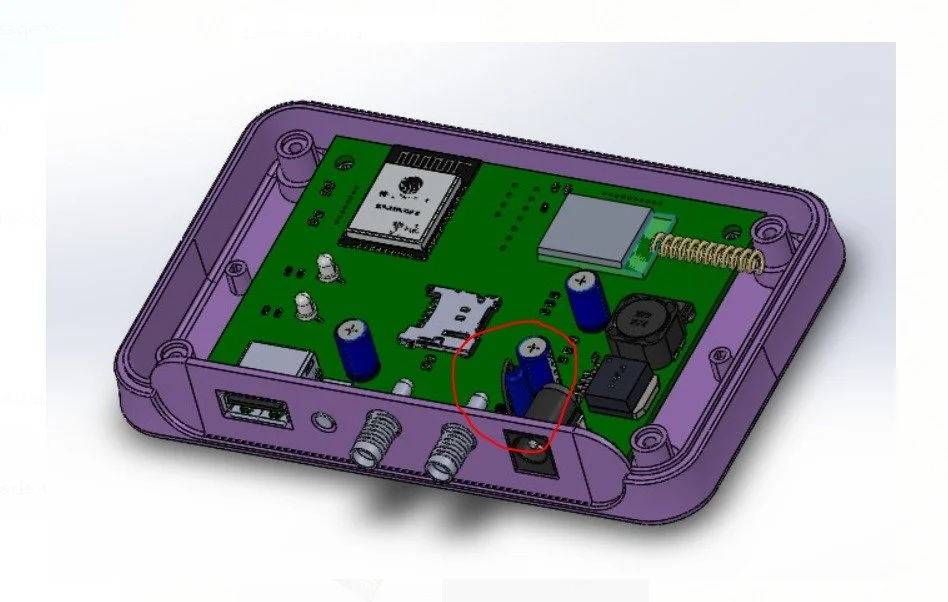

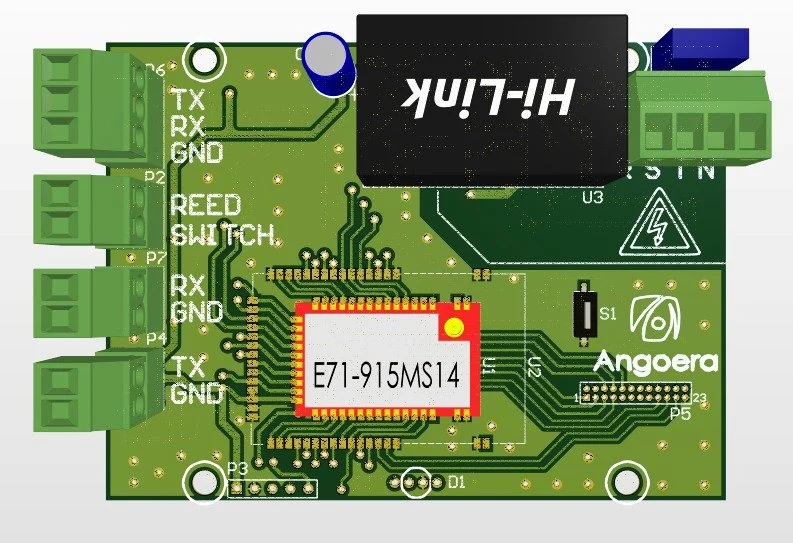

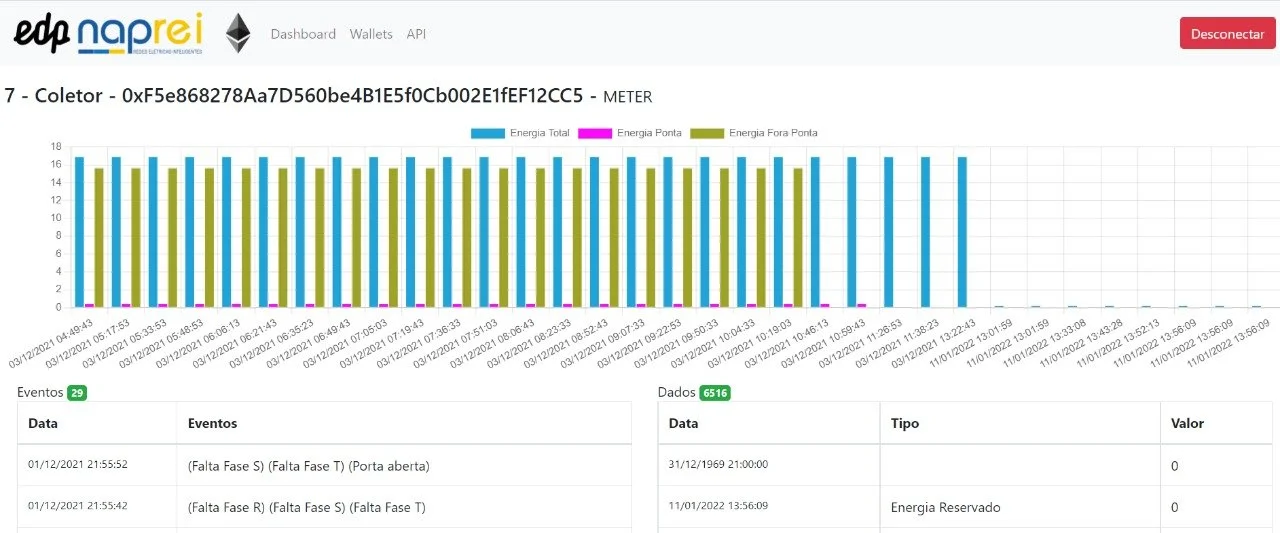

Next-Generation IoT Gateway for Smart Meter Networks

Decentralised Smart Meter Collector with Blockchain Logging

As the lead engineer, I was responsible for both the hardware and firmware development of a robust data concentrator system designed for a Brazilian electric utility company. This system captures energy consumption data from multiple smart meters using RF communication and integrates with blockchain infrastructure for immutable event logging.

System Architecture

The solution is composed of two types of concentrators:

Fixed Concentrator: Permanently installed in the field to perform automated, continuous meter readings.

Mobile Concentrator: Portable unit powered via USB, ideal for drive-by readings in areas without fixed coverage.

Each concentrator integrates:

An RF communication module operating at 915 MHz using the IEEE 802.15.4 protocol in a star topology (supporting up to 100 endpoints per concentrator).

A Raspberry Pi Zero acting as the system controller and gateway.

Technologies and Features

RF controller with support for Wireless M-Bus, 6LoWPAN, and MIOTY.

AC power input (90–245 V) with 3000 VAC isolation and 5000 VAC surge protection.

Visual indicators and isolated input for event detection (e.g., door open, phase loss).

Bluetooth configuration interface for wallet address and Wi-Fi settings using a custom Android app.

Secure communication protocols with AES-128 encryption for RF data.

Event-driven firmware designed to minimize energy consumption while ensuring data integrity.

Blockchain Integration:

Meter readings and events are transmitted to a public Ethereum blockchain.

Firmware manages smart contract transactions triggered periodically (every 30 minutes) or upon specific events (e.g., tampering, power anomalies).

My Contributions

Led the hardware design, including schematic capture, PCB layout, and power circuit design.

Developed the firmware architecture to support automatic collector pairing, data encryption, and event handling without human intervention.

Designed and tested the communication protocols between collectors, concentrators, and the mobile app.

Conducted validation tests for RF range, data accuracy, and smart contract interaction on the blockchain.

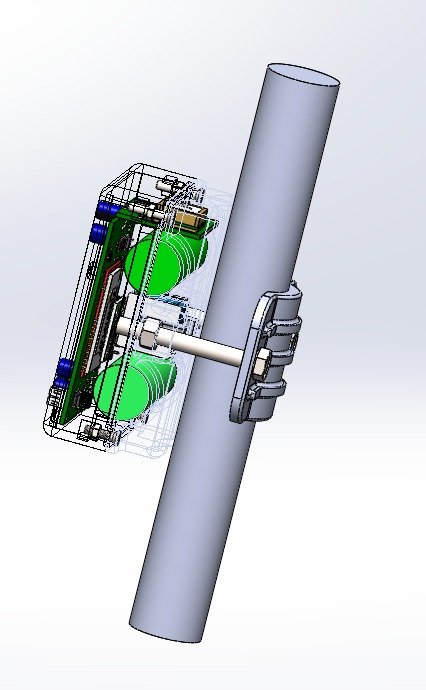

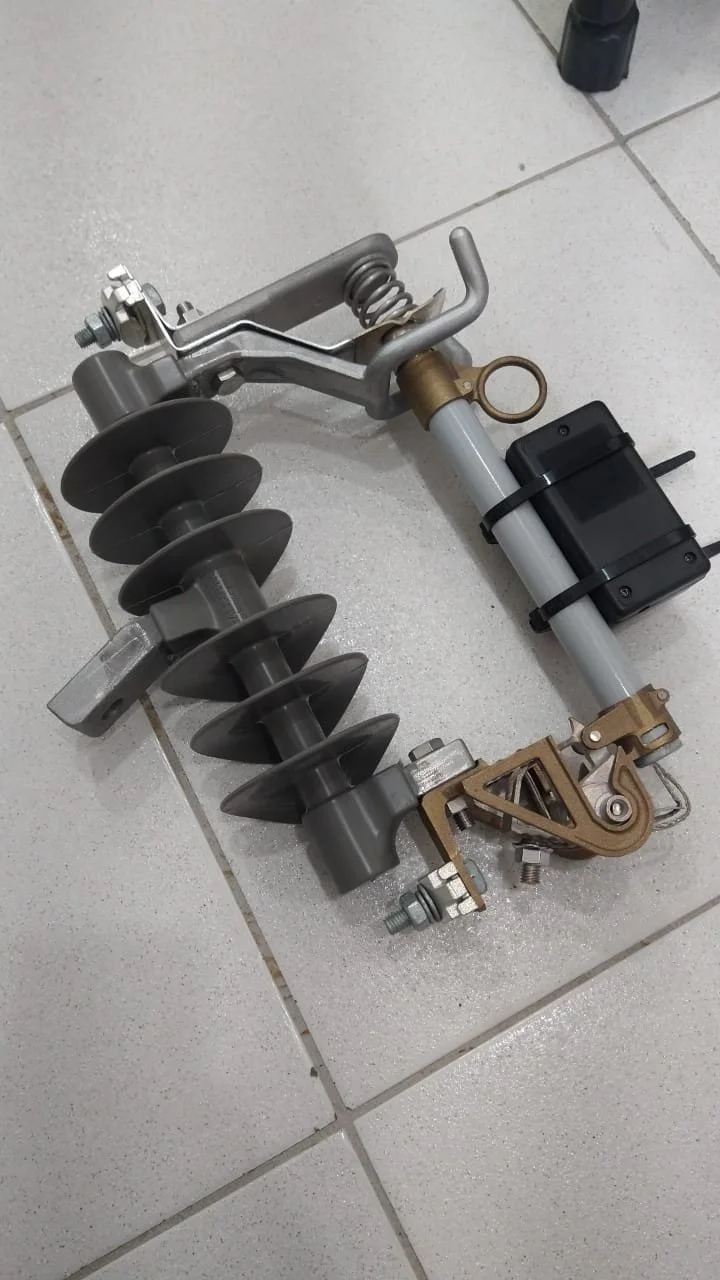

Fuse Sensor and Pole-Mounted Concentrator – Smart Grid Monitoring System

Installed on the power grid’s fuses, it detects electrical presence, physical disconnection, and tampering. It features GPS geolocation and a magnetic field current sensor, operating on ultra-low power with an expected battery life of five years.

Technologies Used

MCUs: TI CC1310 (ARM Cortex-M3) for the sensors; Raspberry Pi SBC (ARM11) for the concentrator

Protocols: IEEE 802.15.4, BLE 4.1, 3G cellular communication

Sensors: MPU6050 accelerometer/gyroscope; magnetic current sensing

Geolocation: uBlox SAM-M8Q GPS module

Power Management: AC input with 3000 VAC isolation; battery operation for sensors

Blockchain: Ethereum smart contracts used to log meter readings and grid events such as:

Fuse disconnection

Power phase loss

Unauthorized access or tampering

Embedded Systems for Sports Biotechnology and Human Performance Monitoring

Embedded Control System for High-Precision Treadmill

I developed the hardware and firmware for a treadmill system designed for precise motor control and real-time monitoring. The solution was based on the AT89S8253 microcontroller (8051 architecture) and featured a modular and robust design suitable for performance and medical applications.

The system integrates key technologies such as dual-motor control with quadrature rotation sensors, analog and digital interfaces for frequency inverter communication (using 12-bit A/D and D/A converters), and PWM control via an H-bridge for incline adjustment. It also includes heart rate signal processing, handling pulse detection and transmission, and a custom serial protocol for PC connectivity. Safety is ensured through limit switches, alarm signaling, and over/under-speed protection.

I was responsible for the complete embedded system development — from hardware schematic design to firmware architecture — delivering a reliable, real-time control platform tailored to the client's specific requirements.

Digital Scale with Strain Gauge Sensing and Serial Communication Protocol

I developed the embedded system for a digital scale focused on force and weight measurement, integrating a high-resolution ADC for strain gauge (load cell) input, a user interface with display and push buttons, and configurable sampling logic. The system supports both automatic and manual acquisition modes, with adjustable parameters such as sample count, sampling interval, and threshold settings.

Data communication is handled via UART, using a custom hexadecimal protocol for reliable exchange with PC software. The firmware was built around a state-machine architecture, supporting real-time acquisition from the strain gauge, error signaling, and structured responses to remote commands. I was responsible for the firmware implementation, ADC and sensor integration, and the serial communication protocol.

The design ensured accurate force measurement and data stability, enabling the integration of the scale into automated analysis and visualization systems.